Tel:

+86 18818786322

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

The socket head cap screw allen key finished product guarantee load test consists of 2 steps:

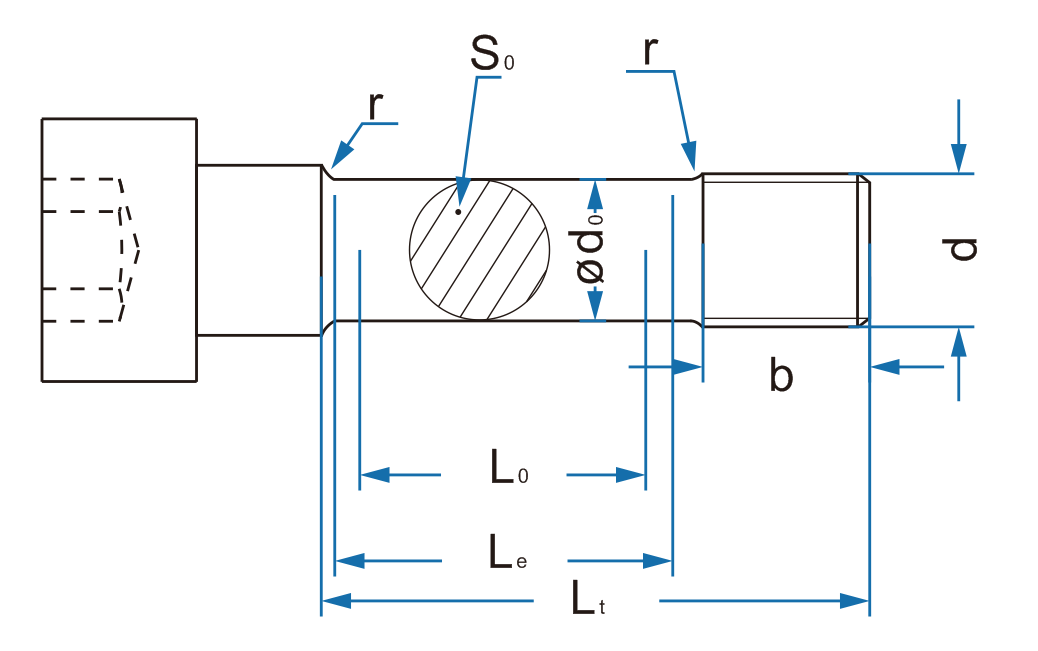

1. Implement the specified guaranteed load. see picture 1

2. Measure the permanent elongation produced by the guaranteed load

Figure 1 Example of installation of guaranteed load on fastener finished product

Suitable for fasteners that meet the following requirements:

1. Bolts and screws with better head bearing capacity than threaded rods

2. The head bearing capacity is stronger than the screw and bolt of the threadless rod

3. No threaded rod diameter ds>d2 or ds≈d2

4. The nominal length of screws and bolts l≥ 2.5d

5. Thread length b ≥ 2.0d

6. The total length of the stud is lt≥3.0d

7.3mm≤d≤39mm

8. All performance levels

socket head cap screw allen key guarantee load test procedure:

socket head cap screw allen key are fasteners that have passed the inspection of size. Each end of the tested screw should be properly machined as shown in Figure 1.

To measure the length (before and after application of the load), the fastener should be placed in a gantry-type measuring instrument with a spherical probe (or other suitable method). Gloves or pliers should be used to minimize measurement errors due to temperature. Measure the total length of the fastener before applying the load.

The fastener test piece will be screwed into the threaded clamp as shown in Figure 1. Two threaded clamps shall be used for the studs. The effective thread length of the threads shall be at least 1d, and the length of the unthreaded threads lth shall be 1d. (Note: In order to meet the requirement of lth=1d, it is recommended to screw the thread clamp to the thread finish and then retract the clamp by the number of buckles equivalent to 1d.

A specified guaranteed load is applied to the fastener axially. The separation rate of the test machine chuck shall not exceed 3 mm/min, and the guaranteed load shall be maintained for 15 s. After unloading, measure the total length of the fastener.

After unloading, the total length l1 of the fasteners shall be the same as before loading l0 (the tolerance of ±12.5 μm is the allowable measurement error). Certain uncertainties, such as straightness, thread alignment, and measurement errors, may cause significant elongation of the fastener when the guaranteed load is applied for the first time. In this case, the test can be performed again using a load that is 3% larger than the values specified in Tables 1 and 2. If the length of the second unloading load (l2) is the same as the length l1 before loading (the tolerance of ±12.5 μm is the allowable measurement error), it shall be considered to comply with the requirements of this test.

If you want to customized socket head cap screw allen key, please send an email: annie.li@szsst88.com

12月-24-2018

kalyn

+86 18818786322

+86 18818786322 sst@szsst88.com

sst@szsst88.com