Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

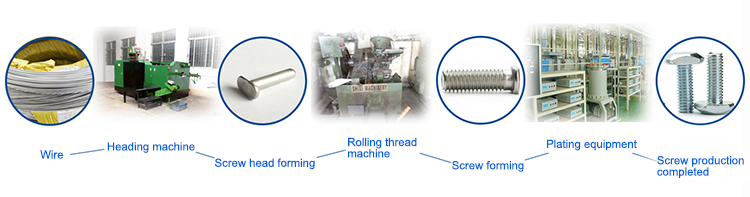

For those who have purchased non standard t head machine screw, the mold is relatively well known, because to produce non-standard screw fasteners, first need to open mold production. Sometimes you may need a mold, sometimes you need a variety of molds to be able to produce, then a non-standard screw, how many molds do you need at least? The following Shi Shi Tong screw manufacturers will briefly introduce how many molds are needed for screw production. First, let’s look at how the screw fasteners are produced:

We can see from the figure that the screw fasteners are from one piece of screw wire to the head forming to the screw forming and then the whole screw is completed. The most basic is to pass these several processes, then in these How many molds does the t head machine screw production need in the basic process?

First of all, the first process that the wire passes through is the head forming. The head contains the head shape of the screw and the groove shape of the screw. For the standard part of the basic screw, the screw head of the standard part only needs to use the single mode. The machine, that is, a mold, can complete the head forming operation. If you want to produce a round head Phillips screw, you only need to use a mold with a cross-shaped groove and a round head to produce it. And the head shape of the screw is so much, a combination of the screw mold also needs a lot. This is a standard part, not a standard one. Some require two molds to work together. For example, a shoulder screw requires two molds to form the head.

The t head machine screw head is formed, and the next step is to the thread decay. Does the thread decay require a mold? This is also needed. We know that the thread of the screw has mechanical thread, self-tapping thread, triangular thread, high and low thread, AB thread, B thread, etc. The dental plates for different thread shapes are not the same, the mechanical thread of this thread, A thread, B thread, triangle thread, these ordinary plate screw manufacturers will basically be equipped, but some customers have special requirements of the thread, you need to re-customize the thread plate.

Basically, the place where the screw needs the mold is the two parts, the head forming and the thread forming. According to the different screw specifications, the number of molds required for the screw is also different. The most basic standard parts require two molds. It can be produced, one is a mold for forming the head, and the other is a mold for forming a thread. If it is a standard screw, then the screw manufacturer will basically be equipped with a mold. Generally, non standard t head machine screw fasteners require a custom mold to be produced, so this also requires a mold opening fee.

If you want to customized t head machine screw please send an email: annie.li@szsst88.com

1 月-07-2019

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com