Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

Aluminum screws are lightweight, corrosion-resistant fasteners made from aluminum or its alloys (e.g., 6061-T6, 7075). They offer a high strength-to-weight ratio, making them ideal for applications where reducing weight is critical, such as aerospace, automotive, and electronics manufacturing. Their non-magnetic and thermally conductive properties suit specialized engineering needs.

Aluminum screws address key challenges in manufacturing:

1.Weight Reduction: 60% lighter than stainless steel, ideal for lightweight designs.

2.Corrosion Resistance: Forms a protective oxide layer, resisting rust in humid or marine environments.

3.Non-Magnetic: Perfect for electronics and MRI equipment.

4.Customizable: Available as machine screws, self-tapping screws, or custom designs to meet specific needs.

However, aluminum screws have lower tensile strength (e.g., 310 MPa for 6061-T6 vs. 800 MPa for grade 8.8 steel), making them unsuitable for high-load structural applications.

1.Aerospace

☁Used in non-structural components like panels and interiors to minimize aircraft weight.

☁Example: Fastening lightweight brackets in satellite assemblies.

2.Automotive

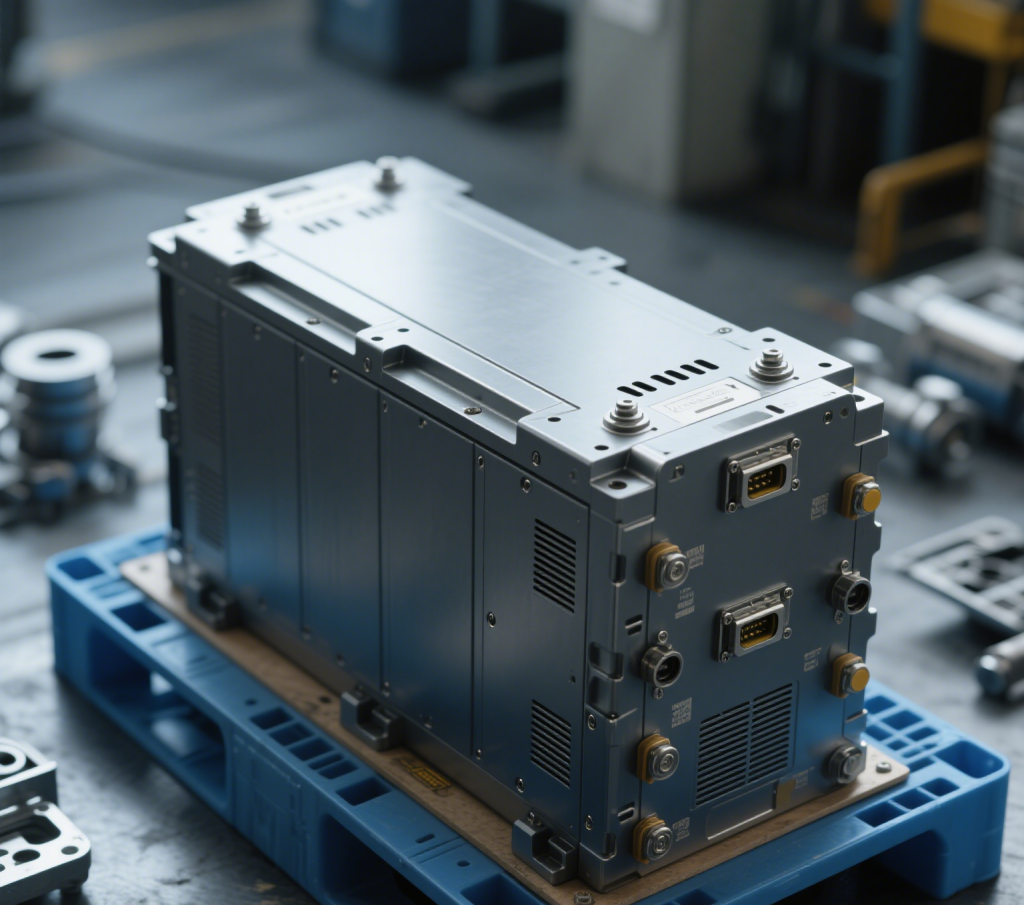

☁Applied in electric vehicle battery casings and trim to enhance fuel efficiency.

☁Note: Avoid high-stress areas like engine mounts.

3.Medical Equipment

☁Non-magnetic screws for MRI machines and portable devices like wheelchairs.

☁Ensures safety and ease of handling.

4.Electronics

☁Used in laptops and smartphones for heat dissipation and EMI shielding.

☁Example: Securing heat sinks in circuit boards.

5.Marine Applications

☁Anodized aluminum screws resist corrosion in saltwater environments.

☁Ideal for boat fittings and coastal structures.

Aluminum screws, such as 6061-T6 (310 MPa tensile strength) or 7075 (550 MPa), offer excellent strength-to-weight ratios but are less robust than steel screws (800 MPa for grade 8.8). They suit lightweight, non-structural applications but may fail under high shear or fatigue loads. For enhanced durability:

1.Use anodized screws to increase hardness.

2.Apply thread-locking compounds to prevent loosening.

3.Avoid over-torquing to prevent thread stripping.

To confirm a screw is aluminum:

1.Weight: Feels significantly lighter than steel or stainless steel.

2.Color: Silvery-white, often with a matte or anodized finish.

3.Magnetism: Non-magnetic (test with a magnet).

4.Markings: Check for alloy grades (e.g., 6061, 7075) or manufacturer stamps.

Self-tapping aluminum screws create their own threads, eliminating pre-drilling in soft materials like aluminum or plastic. Benefits include:

1.Ease of Installation: Reduces assembly time.

2.Reusability: Can be removed without damaging threads.

3.Vibration Resistance: Ideal for automotive and marine applications.

Tip: Use a slow drill speed and cutting oil to prevent overheating or stripping.

A German electric vehicle manufacturer approached Shi Shi Tong to design lightweight, corrosion-resistant screws for battery casings. The client required M6 self-tapping aluminum screws (7075 alloy) with anodized coating to withstand humid conditions. Our team:

1.Conducted a needs analysis to ensure compatibility with aluminum casings.

2.Engineered screws with precise thread profiles to prevent stripping.

3.Delivered 50,000 units within 10 days, meeting DIN 912 standards.

4.Provided torque testing reports to ensure reliability.

The client reported a 15% weight reduction in their battery assembly, improving vehicle efficiency without compromising strength.

|

Screw Type |

Material |

Best Use |

Strength (MPa) |

Corrosion Resistance |

|

Aluminum Machine Screw |

6061-T6, 7075 |

Lightweight, non-structural |

310-550 |

High (anodized) |

|

Self-Tapping Aluminum |

6061, 7075 |

Quick assembly, soft materials |

310-550 |

High |

|

Stainless Steel Screw |

316 Stainless |

High-strength, dry environments |

450-800 |

Moderate (galvanic risk) |

|

Titanium Screw |

Grade 5 Titanium |

High-strength, corrosion-free |

900+ |

Very High (costly) |

Aluminum screws are used in aerospace, automotive, medical, electronics, and marine industries for lightweight, corrosion-resistant fastening.

They are strong for lightweight applications (310-550 MPa) but unsuitable for high-load structural uses where steel or titanium is preferred.

Yes, in dry environments, but use insulating washers or coatings to prevent galvanic corrosion in wet conditions.

Check its light weight, silvery-white color, non-magnetic property, and alloy markings (e.g., 6061).

Shi Shi Tong specializes in custom, non-standard aluminum screws, offering tailored solutions, fast delivery, and ISO 9001:2015 quality assurance.

Need lightweight, corrosion-resistant screws tailored to your manufacturing needs? Contact us for custom solutions. Request a quote today!

|

Skype: kalyn qin M: +86 18818786322 Tel: +86 0755-27322278 Add: Building 9, Tantou First Industrial Zone, Songgang Street, Baoan, Shenzhen 518105, Guangdong Province, China |

5 月-21-2025

Joan

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com