Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

Socket screws are fasteners with a cylindrical head and an internal hexagonal drive (Allen drive), designed for high-torque applications. Unlike traditional screws, they use an Allen key or hex bit, making them ideal for tight spaces and high-strength assemblies in manufacturing and engineering.

Socket screws offer unique advantages for manufacturers and engineers:

1.High Torque: The hexagonal drive resists stripping, ensuring secure fastening.

2.Compact Design: Low-profile heads fit in confined spaces.

3.Versatility: Available in various head styles (cap, button, flat) and materials (stainless steel, alloy steel).

1.Socket Head Cap Screws: Cylindrical head, high strength, used in machinery (ISO 4762 standard).

2.Button Head Socket Screws: Rounded, low-profile head for aesthetic applications.

3.Flat Head Socket Screws: Countersunk head for flush mounting.

4.Socket Set Screws: Headless, used to secure components without protruding heads.

5.Socket Shoulder Screws: Feature a smooth shoulder for precision alignment or bearing surfaces.

|

Feature |

Socket Screw |

Set Screw |

|

Head Type |

Cylindrical, button, or flat head |

Headless |

|

Purpose |

General fastening |

Securing components (e.g., shaft) |

|

Drive |

Hexagonal (Allen) |

Hexagonal (Allen) |

|

Applications |

Machinery, furniture |

Pulleys, gears |

Socket screws are versatile for structural fastening, while set screws are specialized for locking parts in place without a protruding head.

A socket shoulder screw has a smooth, unthreaded shoulder between the head and threaded portion. This shoulder acts as a bearing surface or pivot, ideal for:

-Mold Industry: Guiding stripper plates.

-Automation: Aligning linear guides.

-Precision Equipment: Supporting optical instruments.

A German automation equipment manufacturer approached Shi Shi Tong needing a custom M6 socket shoulder screw with a 10mm shoulder length and titanium alloy construction for a robotic arm joint. The client required high precision (h6 tolerance) and a Teflon coating to reduce friction.

Our team:

1.Designed the screw using CAD to meet exact specifications.

2.Sourced grade-5 titanium for durability.

3.Applied a Teflon coating and conducted torque tests.

4.Delivered 5,000 units within three weeks, improving the client’s assembly efficiency by 15%.

This solution showcases Shi Shi Tong’s expertise in custom non-standard screws tailored to unique engineering needs.

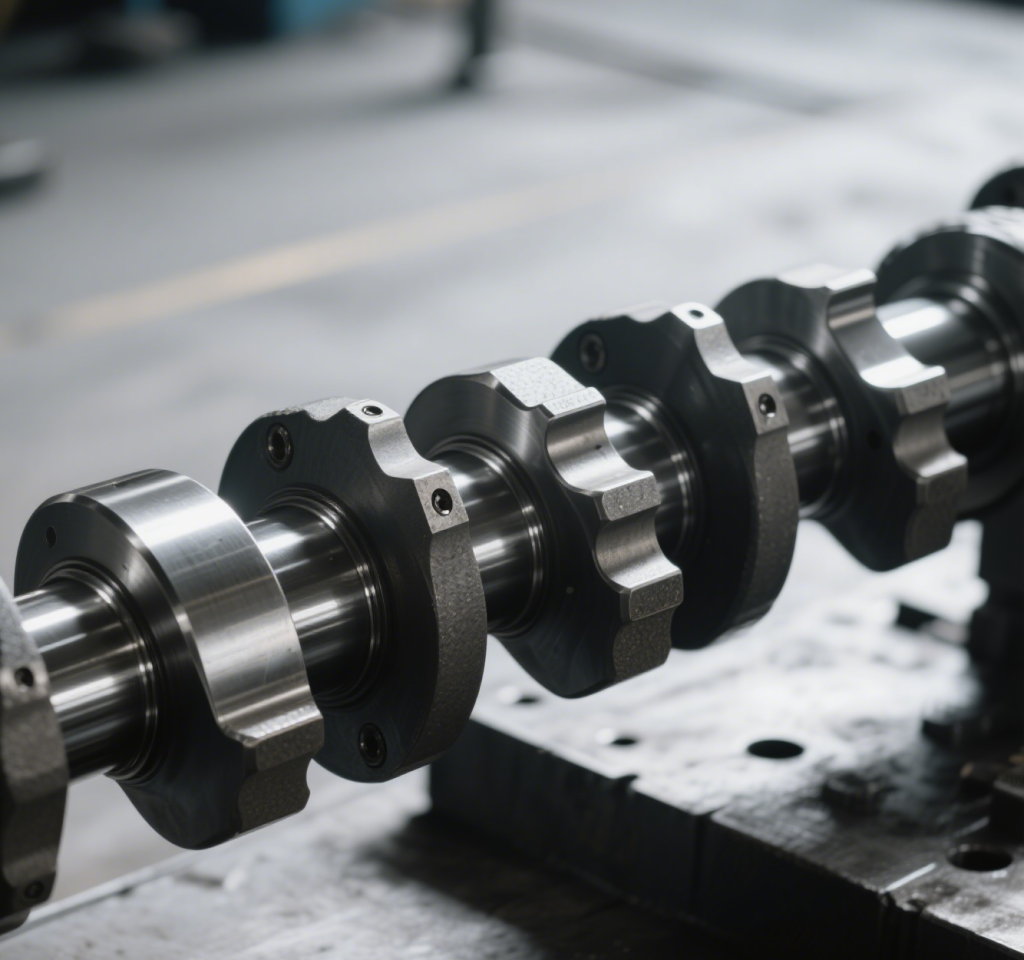

Socket screws are critical in:

1.Automotive: Engine components.

2.Aerospace: Lightweight, high-strength assemblies.

3.Furniture: Hidden fasteners for aesthetics.

4.Machinery: Precision alignment and load-bearing.

At Shi Shi Tong, we specialize in custom non-standard screws. Our process addresses common pain points:

-Complex Specifications: We design screws to exact tolerances.

-Material Selection: Choose from stainless steel, alloy steel, or titanium.

-Fast Turnaround: Prototypes in days, bulk orders in weeks.

A socket screw is a fastener with a hexagonal drive and cylindrical head, used for high-torque applications in machinery and manufacturing.

Socket screws have heads for general fastening, while set screws are headless, used to lock components like gears or shafts.

A socket shoulder screw has a smooth shoulder for precision alignment, commonly used in molds and automation equipment.

Socket screws are essential for high-strength, precision fastening in manufacturing and engineering. Whether you need cap, button, flat head, or shoulder screws, Shi Shi Tong delivers custom solutions to meet your unique requirements. Need custom screws? Contact us today for a tailored quote.

|

Skype: kalyn qin M: +86 18818786322 Tel: +86 0755-27322278 Add: Building 9, Tantou First Industrial Zone, Songgang Street, Baoan, Shenzhen 518105, Guangdong Province, China |

5 月-19-2025

Joan

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com